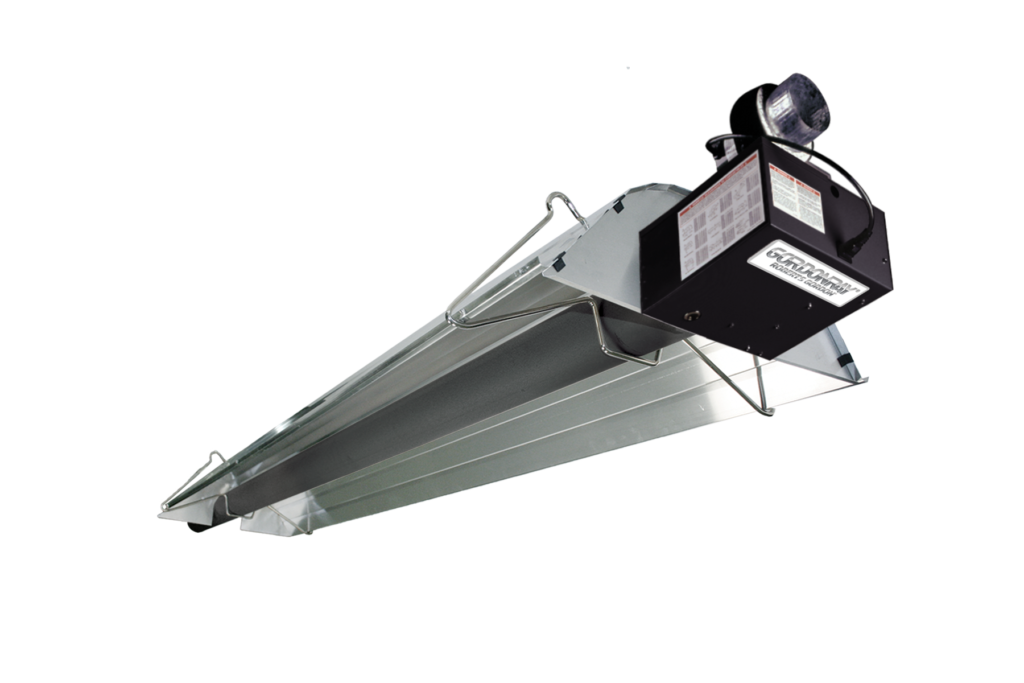

So, after much research and meeting with vendors on various industrial heating options, you finally made the decision to purchase gas‐fired, low‐intensity infrared heaters for your industrial building. Your mechanical contractor completed the installation to the letter and the equipment is up and running. So now you just sit back, relax and bask in the warmth, right?

It’s almost that easy, because radiant industrial heaters are practically bulletproof and can provide years of trouble‐free operation compared to conventional heating systems. When it comes to infrared heating equipment, proper operation and maintenance are just as important as proper installation is to equipment longevity and occupant comfort, especially when you need it the most ‐ during the dead of winter.

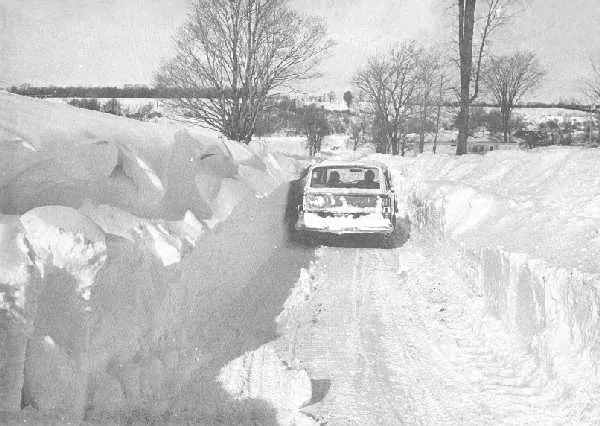

Just ask lifelong residents of Buffalo, New York ‐ the place where gas‐fired, low‐intensity infrared heaters were born almost 60 years ago at Roberts‐Gordon LLC. Buffalonians know a thing or two about brutally cold winters and how to maximize performance of industrial infrared heaters during the most challenging time of the year.

To avoid out of heat situations on some of the coldest days of the year, Roberts‐Gordon offers the following top ten tips to keep your infrared heater in tip top shape.

1. Visually inspect your industrial infrared heater from end to end and perform routine maintenance at the beginning of every heating season. As they say, prevention is the best medicine. The same holds true for infrared heating equipment. Much can be gained by visually inspecting your infrared heater as detailed below.

2. Review the area around the radiant heater – Make sure clearances to combustibles are maintained and do not store or use flammable objects, liquids or vapors near the industrial infrared heater. Do not hang anything from, or place anything on, the infrared heater. Immediately remove these items if violations to clearances to combustibles are found. Make sure the area is clean and free of obstructions to allow adequate space for service or maintenance, as well as to allow for adequate air circulation around the infrared heater.

3. Check the heat exchanger tubing – Visually inspect the outside of the tubing to ensure there are no holes or cracks, especially on the first section of tubing. Make sure radiant tubes are connected and suspended securely. Make sure nothing is touching the heat exchanger tube. For added safety, protective grilles can be attached to the reflectors to prevent objects coming in contact with the radiant heat exchanger tubes.

4. Look at the heater’s venting – Visually inspect the outside vent pipe to ensure there are no cracks or holes. Make sure venting is free and clear of flammable objects or obstructions. It’s recommended to install a bird screen or approved vent cap on the end of the venting to prevent obstructions. Make sure venting is connected and suspended securely and nothing is touching vent pipe. If venting through a combustible wall, make sure approved fire guarding is provided. For unvented operation, make sure mechanical or natural ventilation is operating. Check to ensure there’s adequate separation from any building exhaust or appliance vent pipe to any fresh air intake. Refer to manufacturer’s Installation, Operation and Service manual for distances. During cold weather, ice can build up around or inside venting. Make sure to remove ice if found in these areas. Not only can ice cause potential safety hazards, but it can also adversely affect infrared heater components. Venting should never be installed near doors or other openings where icicles may fall.

5. Inspect reflectors, hangers and reflector supports – Make sure that the reflectors, hangers, and reflector supports are installed as directed in the manufacturer’s Installation, Operation, and Service manual. Proper installation and position of these components is critical to allow the industrial infrared heater to properly expand and contract during the heating season. Make sure reflectors are suspended securely. Check reflector, hangers, wire forms and support straps for signs of dirt, corrosion, sagging or distortion. Make sure nothing is lodged underneath of, or sitting on top of, the reflector. The reflector should never touch the radiant heater tube.

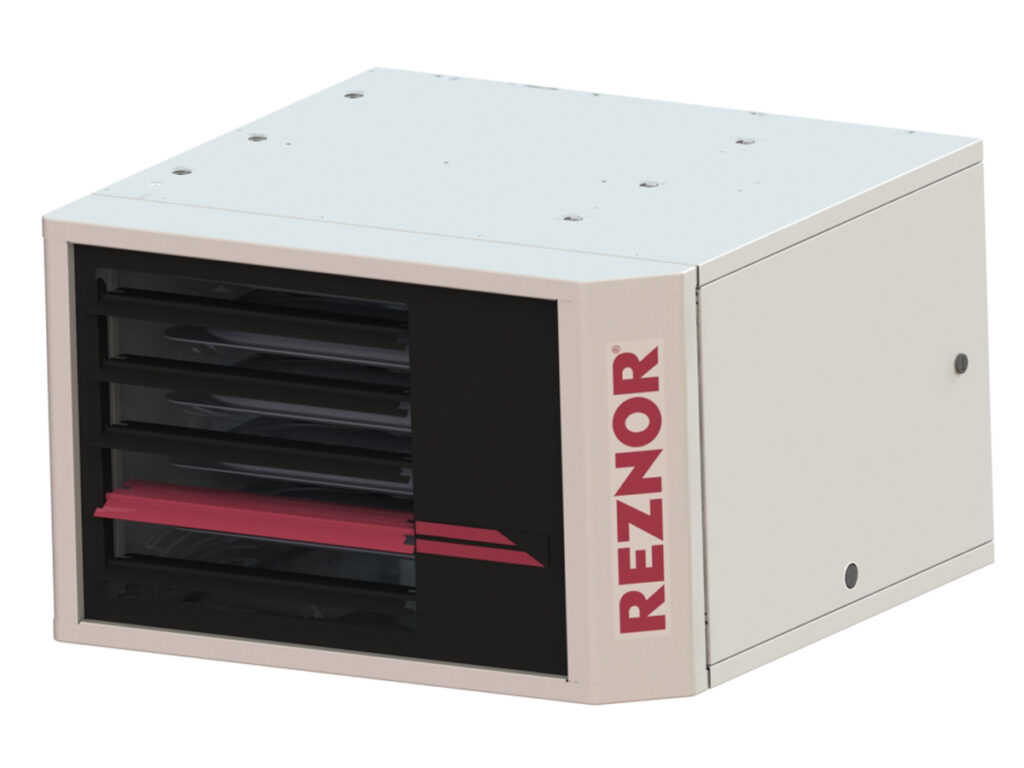

6. Inspect the burner box – Make sure the flame viewer window is clean and free of cracks or holes. Doors must be securely in place. Ensure serial plate and all other labels are legible.

7. Inspect the gas line and gas connection – Make sure gas connection is secure and intact. The gas line should be in a “C” shape with the shut off valve parallel to the burner gas inlet. The gas line should not have any kinks or twists. If gas odor is detected, immediately turn off equipment and contact local gas utility.

8. Look at the fresh air intake (only installed if the system is bringing outside air for combustion to the burner box)-Sometimes, birds, spiders, insects and other critters hunker down inside and block the opening. If this is a common occurrence, it’s recommended to install a bird screen or approved vent cap on the end of the intake to prevent obstructions. Look for condensation forming on the inside of the fresh air intake. Condensation can form on the intake if the inside temperature is much warmer than the cold air coming from the outside to the burner. If condensation appears, wrap fresh air intake with insulation. Check to ensure there’s adequate separation from the heater’s fresh air intake to any building exhaust or appliance vent pipe. Refer to manufacturer’s Installation, Operation and Service manual for distances. During cold weather, ice can build up around or inside fresh air intake. Make sure to remove ice if found in these areas. Not only can ice cause potential safety hazards, but it can also adversely affect infrared heater operation.

9. Perform routine, general cleaning of your low-intensity infrared heater to avoid accumulation of dirt, dust, spider webs and other contaminants or debris. Potential hazards can result when the radiant heater is excessively dirty. Wet a damp cloth with water to clean heat exchanger and reflectors. After cleaning radiant heater, operate for a minimum of 15 minutes to evaporate moisture. Chemicals, such as sanitizers, are not recommended to clean heat exchanger and reflectors. If chemicals are used to clean the infrared heater, the heater must be thoroughly wiped down with a clean, damp cloth. Do not allow chemicals to dry onto radiant heater surface as this may generate odors

10. Consult professionals – The above list provides general guidelines to keeping your industrial infrared heater running smoothly for years to come. This, in turn, helps maintain a safer, healthier and more productive environment. More detailed assistance is available from a variety of sources such as the radiant heating manufacturer. Manufacturers’ websites provide vast content in the form of product specifications, brochures, instructional videos, as well as installation, operation and service manuals.

For local assistance, contact your friendly, local manufacturer’s representative who will be more than happy to perform a site visit. Roberts-Gordon has a wide network of experienced representatives throughout the U.S. and Canada. Please visit www.robertsgordon.com to find a rep near you.

Installation, operation and service of gas-fired, low-intensity infrared heaters must be done by a professional contractor. Contractors install infrared industrial heaters, as well as the gas and electrical supplies, in accordance with applicable specifications and national, state, provincial or local codes.

Another valuable resource is the Infrared Heater Safety Council (IRSC), which is an American Heating Refrigeration Institute (AHRI) initiative focused on education efforts to ensure safe operation of gas-fired, industrial infrared heaters at www.irsafetycouncil.org.

Below are a few additional available resources:

American National Standards Institute (ANSI) – www.ansi.org

CSA Group – www.csagroup.org

National Fire Protection Association (NFPA) – www.nfpa.org